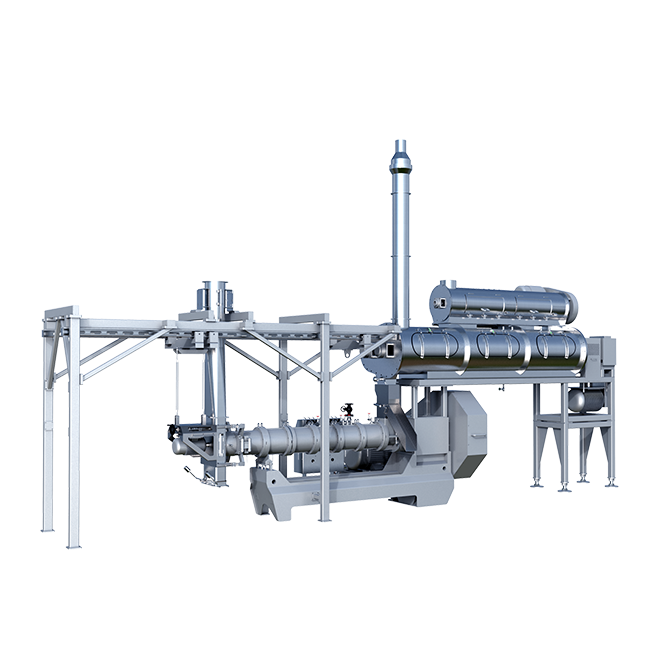

FAMSUN, a leader in the food processing machinery sector, offers innovative solutions for the aquaculture industry. Their SJPS series single-screw aquafeed extruder stands out for its stable operation, high capacity, and low energy consumption. This cutting-edge extruder machine in food industry is designed to enhance efficiency and productivity for aquafeed production.

Optimal Design for Enhanced Performance

The SJPS series features an ideal L/D ratio of 13.1:1, which plays a crucial role in the extrusion process. This design optimizes material flow and heat transfer, ensuring that the final product meets the highest quality standards. With components like bearings and oil seals sourced from top brands, users can expect stable operation and extended equipment life.

Superior Production Capacity

One of the standout features of the SJPS single-screw aquafeed extruder is its impressive production capacity. With output rates exceeding 10% compared to competitors, this extruder machine in the food industry proves to be a game-changer for manufacturers. This enhanced capacity allows businesses to meet growing market demands without compromising on quality.

Energy Efficiency for Cost Savings

In today’s competitive market, energy consumption is a critical factor for operational efficiency. The SJPS series operates at a remarkably low power consumption rate of just 20 to 23 kWh per ton of feed. This energy efficiency not only reduces operational costs but also contributes to a more sustainable production process.

Conclusion

In summary, FAMSUN‘s SJPS series single-screw aquafeed extruder is an essential tool for aquaculture producers seeking stable operation, high capacity, and low energy consumption. Investing in this advanced extruder machine in the food industry will undoubtedly lead to improved production outcomes and profitability.